Title: The Processing of Silk

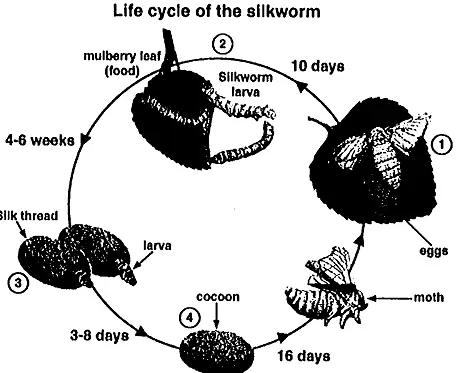

Silk processing is a complex and multifaceted process that begins with the harvest of raw silk worms and ends with the creation of high-quality silk fabrics. The process involves numerous steps, each of which requires precise handling and meticulous attention to detail. From the spinning of the silk threads to the weaving of the fabrics, each step is crucial in ensuring the quality and integrity of the final product.The processing of silk begins with the selection of raw silk worms, which are carefully harvested and then boiled in water to kill them. After this initial step, the worms are dried and their silk glands are extracted, yielding a raw silk material. This raw silk is then cleaned, sorted, and spun into threads, which are then used to weave the fabrics.The weaving process is a skilled and time-consuming task that requires precise manipulation of the threads. The weavers must ensure that the threads are evenly distributed and tightly woven together to create a strong and durable fabric. After the weaving is completed, the silk fabric is then cleaned and dried, ready to be cut and sewn into clothing or other articles of use.Throughout the entire processing chain, quality control measures are taken to ensure that the silk meets high standards of quality and consistency. This includes checking the raw materials, monitoring the processing steps, and testing the finished products. Only when these measures are met can high-quality silk fabrics be produced for use in a variety of applications, from clothing to home decoration.

Silk, a natural protein fiber produced by silkworms, has been a highly valued material for centuries. Its unique combination of strength, softness, and versatility makes it ideal for a wide range of applications, including clothing, accessories, and even industrial uses. However, to ensure the quality and performance of silk products, it is essential to properly process the silk fibers during manufacture.

One of the key steps in silk processing is harvesting the silkworms’ cocoons. The cocoons are collected and then boiled in water to loosen the fibers. After boiling, the cocoons are placed in a solution of acid and water to remove any remaining impurities. This process ensures that the silk fibers are clean and ready for further processing.

Once the silk fibers are cleaned, they are ready to be spun into yarn. This is done by passing the fibers through a series of rollers and heaters, which stretch and align the fibers to create a smooth, continuous yarn. The yarn is then passed through a dye bath to give it color and uniformity. Dying the yarn ensures that the final product will have a consistent color and appearance.

After dyeing, the yarn is ready to be woven into cloth. This process involves passing the yarn through a loom, where it is interlaced with other yarns to create a fabric structure. The fabric is then pressed and finished to remove any remaining wrinkles or imperfections. This step ensures that the final product will have a smooth, professional appearance.

Once the cloth is woven and finished, it can be cut and sewn into garments or other products. This process involves measuring and marking the cloth to ensure that it is cut accurately and uniformly. The cut pieces are then sewn together using thread or yarn to create a final product that is both functional and aesthetically pleasing.

Another important aspect of silk processing is quality control. Throughout the entire process, samples of the silk fibers, yarn, and final products are taken and tested to ensure that they meet specified quality standards. This ensures that the final products are of high quality and consistent performance.

In conclusion, processing silk fibers into high-quality products requires a series of carefully controlled steps. From harvesting the cocoons to weaving the cloth and cutting it into garments, each step must be carefully executed to ensure that the final product is both functional and aesthetically pleasing. Quality control is crucial to ensure that the products meet specified standards and are suitable for their intended applications.

Articles related to the knowledge points of this article:

Title: The Versatile Pairing: How to Wear Grey Suit with a Tie

Title: The Elaborate and Symbolic Significance of Military Dress and Ties

Title: How to Tie a Necktie with a Plain Knot: A Step-by-Step Guide