Title: The Origin of Silk

The Origin of Silk can be traced back to around 5000 years ago, when silkworms were first domesticated in China. From that point on, silk has played a significant role in the history and culture of China, as well as in the global economy. The silk industry has also experienced ups and downs over the centuries, but it has always managed to adapt and survive. Today, China remains the world's leading producer of silk, with a market value of over 100 billion Yuan. The silk industry in China has also evolved to include new products and techniques, such as silk-based clothing, accessories, and even electronic products. This evolution has not only transformed the silk industry but also continues to influence the global economy and culture.

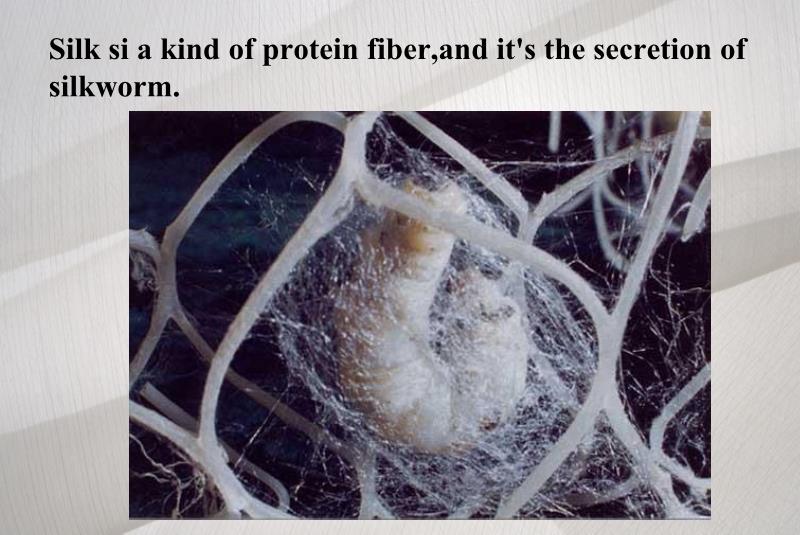

Silk, a natural protein fiber, is produced by certain insect larvae, most commonly by the larvae of the silk moth. The process of how silk is made is both fascinating and complex, involving several stages from the cultivation of the silkworm to the spinning of the silk thread.

1、Cultivation of the Silkworm: The journey of silk production begins with the cultivation of the silkworm, also known as the silkworm. These worms are raised in specific conditions, often in large barns or factories, to ensure their healthy growth and development. The worms are provided with a diet of fresh桑叶 (mulberry leaves), which are their sole source of nutrition.

2、Silk Production: After the worms have grown to maturity, they begin to produce silk. This process occurs when the female silkworm lays her eggs on the桑叶. The eggs hatch into larvae, which then begin to feed on the桑叶. As they grow, they secrete a fluid called “serum,” which is rich in protein and enzymes. This serum, when exposed to air, forms a thin thread that gradually becomes stronger and longer.

3、Harvesting and Spinning: When the larvae have finished growing and producing silk, they are harvested from the桑叶. The silk threads are then collected and spun into a continuous length of yarn. This yarn is further processed to remove impurities and enhance its quality and texture.

4、Weaving and Texturing: The spun silk yarn is then used to weave fabrics that are lightweight, strong, and have a unique texture. The process of weaving involves interlacing the silk threads to create a fabric that is both durable and aesthetically pleasing. The resulting fabric can be further processed to create different textures and patterns.

5、Finished Products: The woven silk fabrics are then used to make a variety of finished products, including clothes, accessories, and even home decoration items. The silk products are often characterized by their elegance, sophistication, and comfort. They are also highly versatile and can be worn in a variety of occasions and settings.

In conclusion, the production of silk is a highly skilled and labor-intensive process that requires a great deal of patience and expertise. From the cultivation of the silkworm to the finished products, each step in the process is crucial to ensure the quality and integrity of the final product. The result is a beautiful, lightweight, and durable fabric that has been prized for centuries for its unique properties and elegance.

Articles related to the knowledge points of this article:

Title: Unveiling a New Era of Formal Attire: The Evolution of Tie-less Suits

Round-necked Down Jacket: A Fashion Trendsetter

The Military Green Jacket: A Winter Staple

Winter Coats: A Must-Have for Cold Weather

White Goose Feather Down Jacket: A Fashionable and Warm Winter Coat