Title: The Silk-making Process: From蚕到蚕丝

The silk-making process, also known as sericulture, is a complex and skilled process that transforms the simple silkworm into a beautiful and useful textile. The process starts with the breeding of silkworms, which are then fed on mulberry leaves until they are ready to spin their cocoons. The cocoons are then collected and soaked in hot water to loosen the silk fibers, which are then drawn out and woven into thread. This thread is then further processed into yarn, which is then woven or knitted into the beautiful fabrics we know as silk. The silk-making process requires a great deal of patience and skill, but the end result is a unique and luxurious textile that has been used for centuries in clothing, accessories, and even in artworks.

When it comes to silk, the first thing that may come to your mind is the luxurious, soft, and often expensive material that is used to make clothes, accessories, and even interior decoration. But have you ever wondered how silk is made? What is the process of turning蚕 into silk?

Well, let’s take a look at the silk-making process from蚕到蚕丝.

Firstly, it all starts with蚕. The silk industry is based on the production of raw silk, which is obtained from the cocoons of certain insects, most commonly the Bombyx mori, also known as the silkworm. The silkworm is a caterpillar that hatches from eggs and feeds on mulberry leaves. As it grows, it secretes a liquid called “serum” into its mouth, which is a type of silk protein. This serum is the precursor of silk fibers.

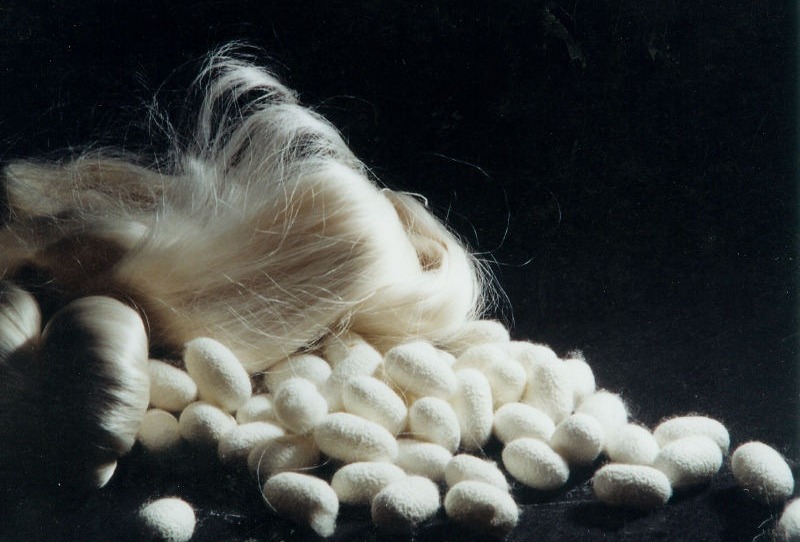

When the silkworm is ready to pupate, it builds a small cocoon around itself using a thread made of its serum. This cocoon is about 5 to 6 centimeters in length and contains the pupa inside. The pupa then transforms into a moth and emerges from the cocoon.

Once the moth has emerged, the cocoons are collected and boiled in water to kill any remaining insect parts and sterilize them. Then, the cocoons are put into a large vessel called a “reeling machine” and spun into a continuous thread of raw silk. This process is called “reeling”. The raw silk is then dried and packaged for storage or further processing.

From raw silk to finished product, there are many steps involved in making silk. The raw silk is first cleaned and then passed through a series of rollers to remove impurities and align the fibers. It is then spun into thicker threads or woven into fabrics. The fabrics are then dyed, printed, or otherwise processed to create the final product.

The silk-making process is not just about turning蚕 into silk; it’s also about preserving and passing on a centuries-old craft that has been passed down through generations of artisans. It’s about creating beautiful, functional products that are not just fashionable but also sustainable and environmentally friendly. By understanding the silk-making process, we can better appreciate the effort and skill that goes into creating each and every piece of silk that we wear or use in our daily lives.

Moreover, the silk industry provides jobs and income for many people around the world, especially in rural communities where the industry is often a main source of livelihood. By supporting sustainable and ethical silk production, we are not just supporting a beautiful craft but also helping to improve the lives of those who depend on it for their livelihood.

In conclusion, understanding the silk-making process from蚕 to蚕丝 not only allows us to appreciate the beauty and value of silk but also to understand its importance in our global economy and culture. Whether you are looking to buy a luxurious silk dress or simply want to learn more about this fascinating material, understanding its origins and production process is always a good place to start.

Articles related to the knowledge points of this article:

Is Ducks and Ducks Down Jacket a Brand or Not?

Title: Mastering the Art of Mens Tie Knotting: A Comprehensive Guide for Every Man

Title: The Evolution and Origin of Ties: A Journey Through Time

Title: The Perfect Pairing: How to Match a Dark Suit with a Tie