Carpet Machines: Types and Their Applications

Carpet machines are essential tools for carpet manufacturing and installation. There are several types of carpet machines, each with its own specific application. For example, tufting machines are used to create the carpet face, while weaving machines are used to produce the backing. Other types of carpet machines include finishing machines, which are used to apply finishes and coatings to the carpet, and stretching machines, which are used to stretch and install the carpet.Carpet machines come in a range of sizes and configurations, depending on the specific application. For instance, some machines are designed for small-scale production, while others are suitable for large-scale manufacturing. Additionally, some machines come with advanced features, such as computer-aided design (CAD) software, which allows for the creation of complex carpet patterns.In terms of application, carpet machines are used in a variety of settings, including residential, commercial, and industrial environments. For example, they are commonly used in carpet factories to produce carpets for sale to consumers. They are also used in offices, hotels, and other public spaces to create comfortable and aesthetically pleasing environments.Overall, carpet machines play a crucial role in the production and installation of carpets. By understanding the different types and their specific applications, it is possible to choose the right machine for any given task, ensuring efficient and high-quality results.

In the world of textiles, carpet machines play a crucial role in the production of high-quality carpets. These machines come in various types, each designed for a specific task in the manufacturing process. From tufting machines that create the pile of the carpet to weaving looms that produce the foundation, these are some of the key types of carpet machines used in the industry today.

Tufting Machines

Tufting machines are responsible for creating the pile of the carpet. They do this by punching loops of yarn through a base material, typically made of jute or polyester. This process gives the carpet its thickness and softness. Tufting machines come in different varieties, including single-needle, double-needle, and multi-needle models. The type of yarn used and the desired density of the pile determine which machine is best suited for a particular task.

Weaving Looms

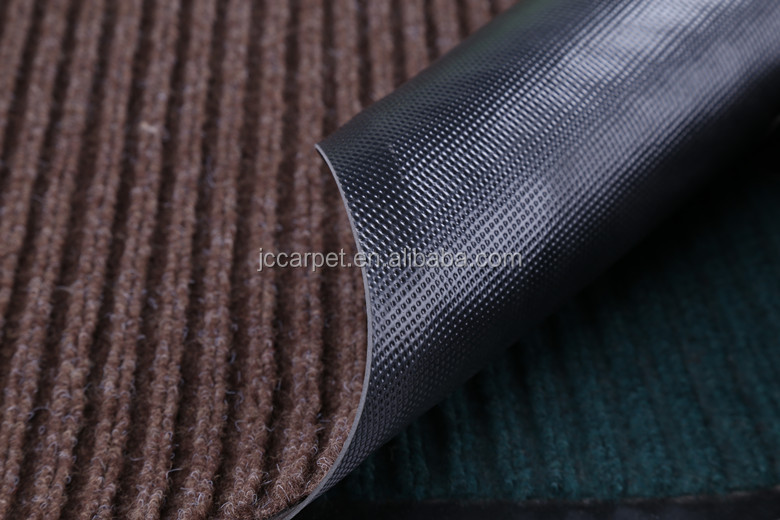

Weaving looms are responsible for producing the foundation of the carpet. These machines come in both automatic and semi-automatic varieties and use techniques like weaving, picking, and pressing to create a strong and durable base for the pile to adhere to. The type of loom used depends on the size, shape, and material of the carpet being produced.

Other Types of Carpet Machines

In addition to tufting machines and weaving looms, there are other types of carpet machines used in the manufacturing process. These include binding machines that bind the edges of the carpet to prevent fraying, printing machines that apply patterns or designs to the carpet, and finishing machines that complete the look and feel of the final product.

Applications of Carpet Machines

Carpet machines have a wide range of applications in both commercial and residential settings. Commercial applications include hotels, restaurants, offices, and public buildings, where carpets are used for their aesthetic appeal and to provide comfort underfoot. Residential applications include homes, where carpets may be used in bedrooms, living rooms, or hallways to add warmth and style to a space.

Conclusion

The types of carpet machines used in manufacturing vary depending on the specific task at hand, from creating the pile with tufting machines to weaving the foundation on looms. These machines play a vital role in the production of high-quality carpets for both commercial and residential use. With advances in technology, we can expect to see even more innovations in carpet machine design and functionality in the future.

Articles related to the knowledge points of this article:

Title: The Art of Suit Jacket and Tie Photos: Capturing the Essence of Confidence and Sophistication

Title: Should Men Wear Ties to Their Wedding?

Title: The Perfect Pairing: How to Match a Navy Blue Suit with a Tie

Outfit Ideas for Medium-Long羽绒服

Title: The Down Jacket Group Purchase

Title: The Art of the Silk Scarf: A Tale of a Fashionable Lady