Title: The Art and Science of Sofa Manufacturer

The art of sofa manufacturing is a combination of science and creativity. Sofa manufacturers use various materials such as leather, fabric, and foam to create comfortable and stylish seating options. The process starts with designing the sofa's structure and shape, followed by selecting the appropriate materials and cutting patterns. Once the basic framework is in place, the manufacturer applies upholstery techniques to give the sofa its final look. Science plays a crucial role in ensuring the durability and comfort of the sofa. Manufacturers use scientific methods to measure the materials' properties, including elasticity, firmness, and breathability. They also test the sofa's structural integrity before it leaves the factory. At the same time, creativity is essential in making a sofa that looks appealing and unique. Sofa manufacturers use innovative designs, colors, and textures to make their products stand out from the competition. Additionally, designers work closely with customers to understand their preferences and incorporate them into the sofa's design. In summary, the art and science of sofa manufacturing go hand in hand. While science provides a solid foundation for creating functional and comfortable products, creativity adds beauty and individuality to each piece. By combining both aspects, sofa manufacturers can produce high-quality furniture that meets customers' needs and expectations.

As human beings, we are constantly seeking comfort and relaxation in our daily lives. One of the most essential pieces of furniture that provides us with both is the sofa. A sofa is not just an object of utility but also a work of art that can transform any space into a cozy, inviting haven. The process of creating a sofa involves a complex interplay of design, materials, engineering, and craftsmanship, all of which are handled by sofa manufacturers.

A sofa manufacturer is a business entity that engages in the production of sofas. Their role is multifaceted and involves various stages, from design and planning to manufacturing, assembly, and distribution. The success of a sofa manufacturer depends on their ability to balance these different aspects effectively. In this article, we will delve deeper into the world of sofa manufacturing, exploring its challenges, opportunities, and future trends.

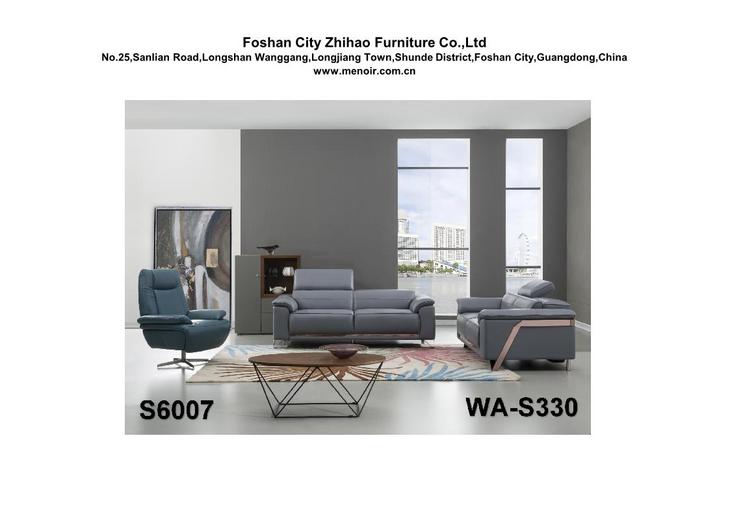

Design is the cornerstone of any successful sofa manufacturing process. It involves creating prototypes, choosing materials, developing patterns, and testing them to ensure they meet the desired specifications. A great sofa design should not only look good but also be comfortable, durable, and affordable. To achieve this balance, sofa manufacturers often collaborate with renowned designers and incorporate innovative features such as ergonomic support, modular components, and eco-friendly materials.

Once the design is finalized, the next step is to select the right materials. Sofas can be made from a variety of materials such as leather, fabric, wood, foam, and recycled materials. Each material has its own set of advantages and disadvantages, such as durability, comfort, maintenance, and environmental impact. Sofa manufacturers need to carefully evaluate these factors and choose the ones that best suit their customers' needs and preferences.

After selecting the materials, the manufacturer moves onto the manufacturing stage. This involves cutting, stitching, sewing, bonding, and shaping the different components into a cohesive whole. The manufacturing process requires precision, speed, and efficiency, as well as attention to detail to ensure quality control. Sofa manufacturers often use advanced technologies such as robotics, automation, and 3D printing to streamline their operations and improve productivity.

Once the manufacturing is complete, the next step is to assemble the sofas. This involves connecting the different parts together and attaching any additional features such as cushions, pillows, or covers. Sofa manufacturers must ensure that the assembled product is stable, comfortable, and meets the safety standards. They also need to comply with environmental regulations such as waste management and energy consumption.

The final stage in the sofa manufacturing process is distribution. Sofa manufacturers sell their products to retailers or directly to consumers through online platforms or physical stores. The distribution process involves logistics, marketing, pricing, and customer service to ensure that the sofa reaches its destination in perfect condition. Sofa manufacturers must also consider factors such as import/export regulations, cultural differences, and market trends when expanding their reach.

In conclusion, sofa manufacturing is a complex and challenging process that requires a high level of expertise and dedication. From designing innovative solutions to choosing sustainable materials and providing excellent customer service, sofa manufacturers play a crucial role in creating comfortable and beautiful living spaces for people around the world. As technology continues to advance and consumer preferences evolve, sofa manufacturers will need to adapt and innovate continually to stay ahead in a competitive market. However, with their passion for excellence and commitment to their craft, they will continue to make a lasting contribution to the world of home furniture.

Articles related to the knowledge points of this article:

Title: Mastering the Art of Tying a Tie: A Comprehensive Guide

Title: The Art of Tie Knotting: A Comprehensive Guide to Tie Tying Techniques

Title: A Comprehensive Guide to Silk Scarves: A Picture Gallery of Exquisite Fabrics

Title: Innovative ways to store scarves: A comprehensive image guide

Title: Mastering the Art of Tie-Dyeing with Silk Scarves: A Step-by-Step Guide for Beginners