Title: The Art of Carpet Making: From Fiber to Finished Product

The art of carpet making is a meticulous process that dates back centuries. From fiber selection to the finished product, each step requires skill and patience. The process starts with the selection of raw materials, such as wool, silk, or synthetic fibers. These materials are then processed, cleaned, and dyed to achieve the desired color and texture. Next, the fibers are spun into threads and then interlaced to form a base for the carpet. This base is then covered with a layer of yarn, which is knotted and then cut to create the pile of the carpet. Finally, the carpet is inspected for quality assurance and then ready for use in homes and businesses. The art of carpet making is not just about creating a functional item but also about creating something that is both beautiful and durable.

Carpet making is a highly skilled craft that dates back over 5,000 years. Originating in the Middle East, this art form has since spread throughout the world, becoming a staple in both commercial and residential settings. From its humble beginnings as a utilitarian item, the carpet has evolved into a decorative and artistic expression, telling stories through its patterns and colors.

The first step in carpet making is selecting the fiber. The most common fibers used are wool, silk, and synthetic materials like nylon and polyester. Each fiber has its own unique set of properties that affect the final product’s appearance, durability, and cost. For example, wool carpets are known for their softness, durability, and ability to insulate, while silk carpets are prized for their elegance and luster.

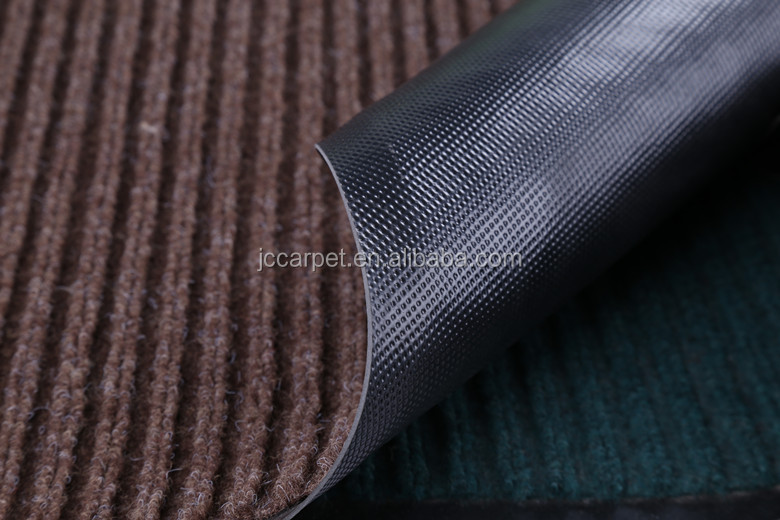

Once the fiber is selected, it must be processed and transformed into a form suitable for weaving. This often involves cleaning, dyeing, and weaving the fiber into a loose pile. The pile is then cut to the desired length and thickness, creating the final appearance of the carpet.

The next step is the actual weaving process. Weavers use a loom to create the foundation of the carpet, typically a series of parallel threads called the warp. The weaver then interlaced these warps with a series of horizontal threads called the weft. This process creates the grid-like pattern that forms the basis of the carpet’s design.

After the foundation is complete, the weaver can begin adding color and pattern to the carpet. This is done by using different colored threads or adding patterns to the loom before weaving. Traditional patterns like medallions, arabesques, and geometric shapes add both beauty and meaning to the finished product.

Finally, once the carpet is completely woven and patterned, it must be finished and inspected. This involves trimming any excess fiber, binding the edges to prevent fraying, and often applying a protective coating to enhance durability. The finished carpet is then inspected for any defects or imperfections before being packaged and shipped to its final destination.

In conclusion, carpet making is a complex and skilled craft that requires a great deal of attention to detail and expertise. From selecting the fiber to weaving the foundation and adding patterns, each step requires knowledge and expertise passed down through generations. The resulting carpet is not only a functional item but also a work of art that can enhance any home or business.

Articles related to the knowledge points of this article:

Title: The Art of Pairing a Black Suit with a Tie

The羽绒外套: Fashion and Functionality

Title: The Story of a Goose in a Down Jacket

Title: Mastering the Art of Tie Tying: A Quick Guide to Tie Knots